BLOG

-

Métodos de tratamiento de superficies comúnmente utilizados para metales.

1.Tratamiento de recubrimiento: Uno de los métodos comunes de tratamiento de superficies para hardware es el tratamiento de recubrimiento, como galvanizado, niquelado y cromado.Los recubrimientos proporcionan una capa protectora sobre la superficie del metal, mejorando su resistencia a la corrosión y mejorando la apariencia...Leer más -

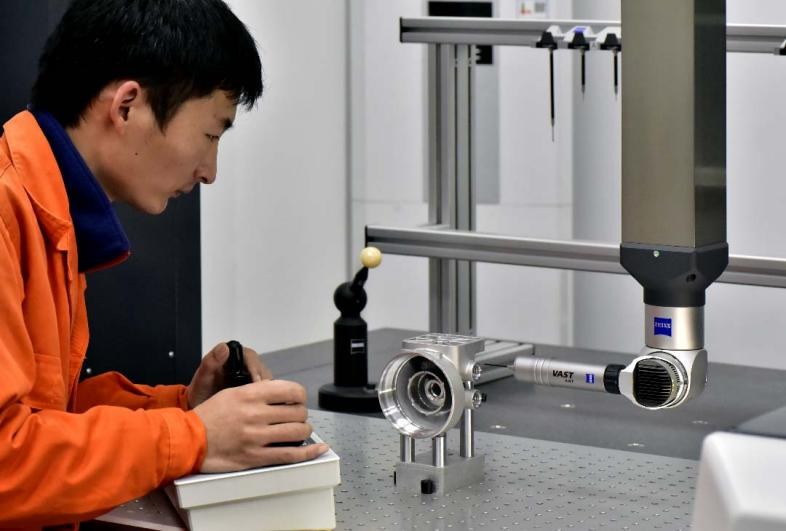

Garantizar el cumplimiento de la calidad de las prácticas de control de calidad de piezas metálicas en Xiamen Ruicheng

El propósito del control de calidad no es sólo prevenir defectos, sino también garantizar que las piezas se fabriquen de acuerdo con las especificaciones de diseño y funcionen correctamente.Un buen programa de control de calidad ayuda a mantener la producción a tiempo y dentro del presupuesto, y también ayuda a evitar el producto...Leer más -

¿Qué es el estampado?

El estampado es un proceso de fabricación que se utiliza para dar forma a láminas o tiras de metal aplicando fuerza a través de un troquel o una serie de troqueles.Implica el uso de una prensa, que aplica presión sobre el material metálico, provocando que se deforme y adopte la forma del troquel....Leer más -

¿Qué es la extrusión?

La extrusión es un proceso de fabricación que se utiliza para crear objetos con un perfil de sección transversal fijo empujando o forzando un material a través de un troquel o un conjunto de troqueles.El material, a menudo en estado calentado o semifundido, se fuerza a alta presión a través de la abertura del...Leer más -

¿Qué es la fundición a presión?

La fundición a presión es un proceso de fundición de metal en el que se inyecta metal fundido, generalmente una aleación no ferrosa como aluminio, zinc o magnesio, a alta presión en un molde de acero reutilizable, llamado matriz.El troquel está diseñado para formar la forma deseada del producto final....Leer más -

Explorando materiales metálicos comunes: el poder de la fuerza, la diversidad y la innovación infinita

área de aplicación característica de los materiales Aleación de aluminio La aleación de aluminio es un material metálico liviano con buena resistencia y resistencia a la corrosión.Se utiliza ampliamente en componentes automotrices, carcasas de productos electrónicos y artículos para el hogar.Acero inoxidable Acero inoxidable...Leer más -

Métodos comunes para personalizar el metal

Al personalizar productos metálicos, elegir el método de procesamiento adecuado es fundamental para la calidad, el costo y el tiempo de entrega del producto. Existen varios métodos comunes para personalizar metales.A continuación se muestran varios métodos de personalización de metales de uso común: 1.Mecanizado CNC: C...Leer más -

¿Qué son las tolerancias geométricas?

ISO define las tolerancias geométricas como "Especificaciones geométricas del producto (GPS) − Tolerancias geométricas − Tolerancias de forma, orientación, ubicación y excentricidad".En otras palabras, "características geométricas" se refiere a la forma, tamaño, relación posicional, etc. de un objeto...Leer más -

Cómo conseguir un buen revestimiento de piezas de plástico.

El revestimiento de plástico es un proceso de revestimiento que se ha utilizado ampliamente en la industria electrónica, la investigación de defensa, los electrodomésticos y las necesidades diarias.La aplicación del proceso de revestimiento de plástico ha ahorrado una gran cantidad de materiales metálicos, su proceso de procesamiento es simple...Leer más